We had an incredible time attending the 66th International Technical Fair in Belgrade, Serbia this year! It was an amazing opportunity to connect with industry leaders, discover innovative products, and gain valuable insights from our partners.

Thanks to all and we are already looking forward for the next year’s event.

Powering the Future with Clean Energy: Introducing Our Second Roof Solar Plant

We are thrilled to announce the launch of our second 270 kWp roof solar plant, another step towards a sustainable and energy-efficient future. Harnessing the limitless power of the sun, our solar plant is a testament to our commitment to environmental awareness and innovation. With cutting-edge technology and a dedication to renewable energy, we’re proud to contribute to a greener world. Join us in paving the way for a brighter tomorrow through clean energy solutions.

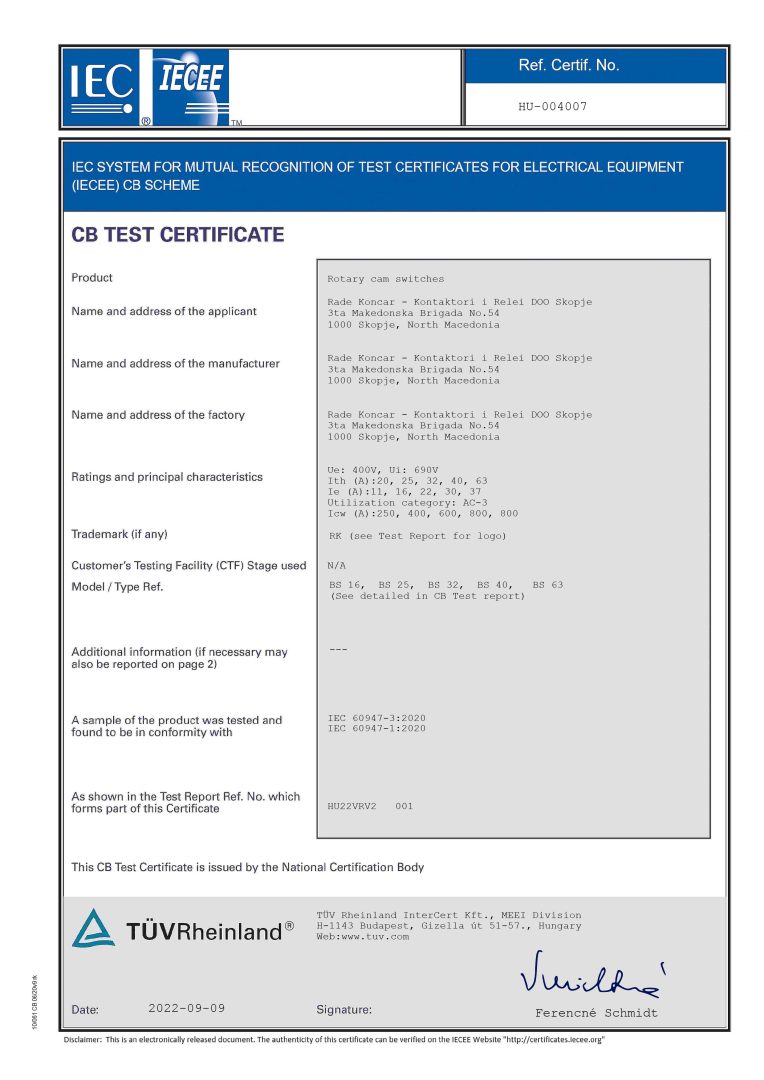

Rotary Cam Switches Certification

One more validation for our hard work and dedication. We have just certified our Rotary Cam Switches from 16 to 63 amperes.

The tests were carried out in accordance with the IEC system for mutual recognition of test certificates for electronic equipment (IECEE) CB SCHEME. Our rotary cam switches with commercial names BS 16, BS 25, BS 32, BS 40 and BS 63 were tested and found to be in conformity with the standards IEC 60947-3:2020 and IEC 60947-1:2020.

Together with our contactors series CNN, CNM and CNNK we now have a certified production of ROTARY CAM SWITCHES – RADE KONCAR KONTAKTORI I RELEI.

New solar plant 400kWp

We have just finished our 400kWp solar plant installed on the roof of our production facility.

This solar system is one big step towards fulfilling our strategy to manufacture green products using energy from sustainable sources. For this project we have used one of the credit lines of the European Bank for Reconstruction and Development (EBRD), for increasing competitiveness of small and medium-sized enterprises in North Macedonia.

Hannover Messe 2022

For two years the entire world stopped because of the corona pandemic. We were locked up within the borders of our own countries and could not travel. We at Rade Koncar Kontaktori i Relei DOO used this period to develop new products and improve production. Today we were happy to exhibit the new products at the World Industrial Fair in Hanover. Hannover is one of the world’s largest industry fairs and for us it is the most important fair we participate in every year for the last 25 years.

Innovation at the core of our technology

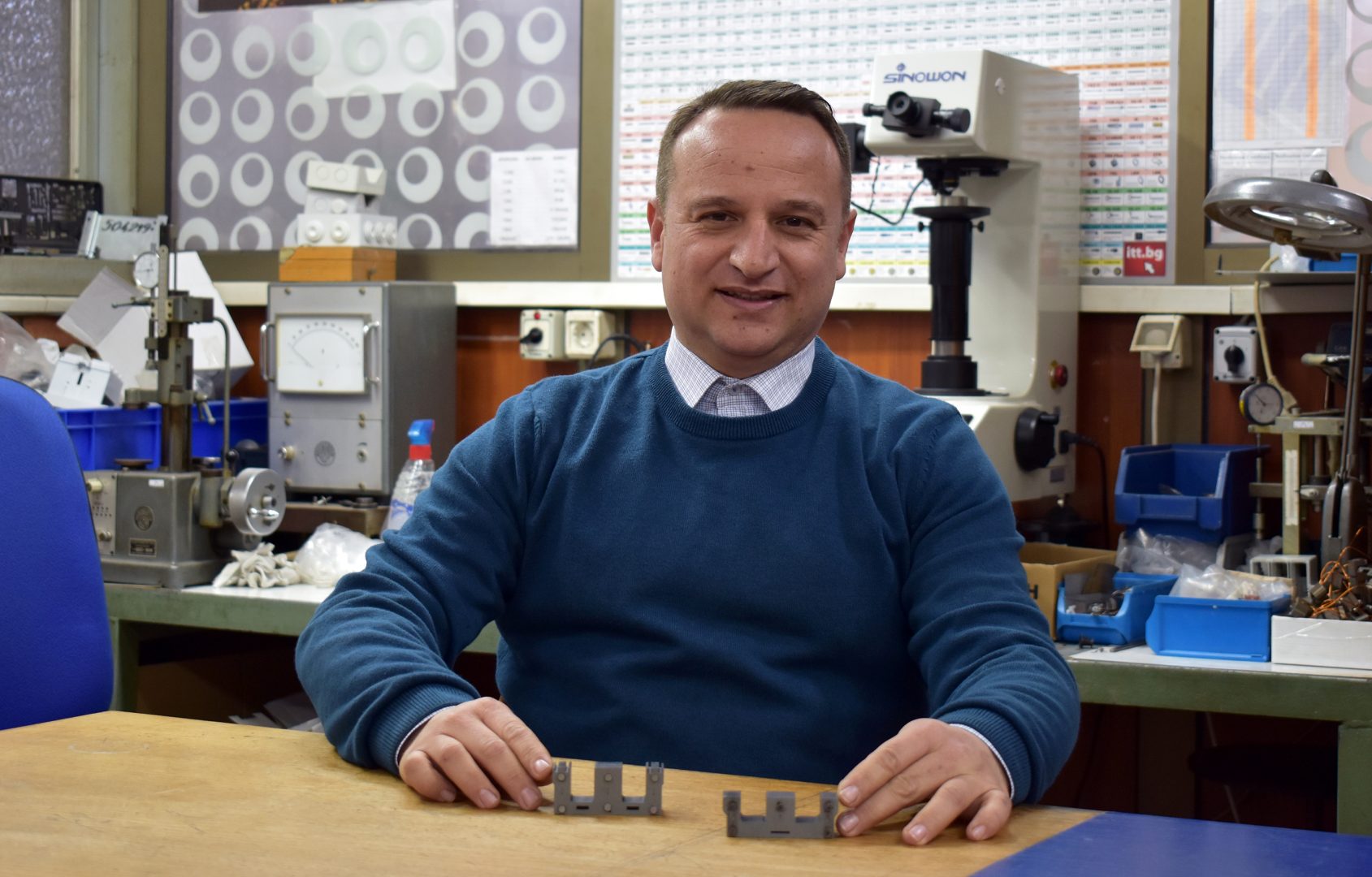

Innovation always helps us to develop products that will result in better quality, while reducing the production time and the amount of resources used. In the development of our new products – motor contactors CNN 150 and capacitor contactor CNNK 80, a project supported by the Fund for Innovation and Technological Development, the technology department designed and manufactured a device for assembling the yoke and core. This new device has the status of an innovation in our work because for the first time 4 working operations are integrated in one device.

The experience of product development in the past has led us to think differently and try to use innovative methods to solve the challenge in the production processes. The development technology team led by the Eng. Goran Zdravkovski gave a great contribution in improving the technological line for the production of the new contactors. In addition to this successfully designed device, we are dedicated to develop such innovative processes in all parts of production. Improving the production process in our factory is based on such marvelous people… we are happy to have you with us.

Our company’s role in community sustainable development

We are already focused on designing and creating products which reduce energy use and CO2 emissions. Also, we are making effort to use energy for our production from renewable sources.

As a way of expressing our constant focus to our mission – to make the world a greener place to live in, we as a company have organized an event to plant trees in our yard.

This time we took a different approach and wanted to focus more on our surroundings. We invited company employees to take part in planting trees around our facility.

With this event our facility looks nicer surrounded with trees. But the effect is far from pure aesthetics, it is also beneficial, especially with the high air pollution in Skopje. In this regard, we did something for our community as well.

We also found common grounds with the Municipality of Aerodrom, in making the city greener. As a bigger company from this municipality, we would like to set an example for the others to follow.

Making the world a better place – one step at a time

Ethics in the workplace is defined as the moral code that guides the behavior of employees with respect to what is right and wrong in regard to conduct and decision making.

The ethical behaviour is essential for society to function properly. It is both the right thing to do and the best business approach.

Ethical behaviour in the workplace can stimulate positive employee behaviours that lead to company’s growth. And vice versa, unethical conduct can lead to company’s stagnation.

Therefore, we put words in practice and have created an ethical platform. This platform consists of many policies, programs and processes, rising from our values and purpose.

1. Code of Ethics and Business Conduct

We have created a special Ethic Program to demonstrate our commitment to ethics, integrity and uncompromising values. All our employees are expected to comply with the values, principles and procedures. We are working on the internal communication and raising awareness about the ethical behaviour. In addition, an Ethics Committee has been established to act as an independent advocate for employee ethics concerned and to be the lead of this important Program.

2. Anti-discrimination and harassment policy

As a company we are committed to a diverse workforce and ensuring that we are part of a discrimination and harassment free work environment. We have also established ourselves as equal opportunity employer and try to create a safe environment full with respect for diversity.

3. Corporate Social Responsibility Policy

This policy has the objective to create and promote behaviour that generates value to all interest groups, such as customers, employees, suppliers, environment and shareholders in the context of socially responsible culture.

We commit to continuous communication to all related groups, to creating listening mechanisms through which we can all identify relevant subjects in order to establish stable relationship.

4. Anti-slavery or human trafficking policy

We have a zero-tolerance approach to modern slavery and we are committed to acting ethically and with integrity in all our business dealings and relationships and to implement and enforce an effective systems and controls to ensure modern slavery is not taking place anywhere in our business or our supply chain.

5. Equality, Diversity and Inclusion Policy

This policy ensures that we as a company offer equal opportunity for all contacts regardless of their diverse personal characteristics. For us diversity means recognizing and valuing difference in its broader sense.

Taking all the above in count, all the policies, programs etc. we strive to be recognised as a company with high integrity and ethical standards. We focus on our values and purpose to drive our long-term thinking and to make the world a better place for all our employees, suppliers, stakeholders and the environment in whole.That is way we are respected among our partners as a company with high business standards and integrity.

How to minimize the damage and maximize the output: e-camguard implementation

Manufacturing process is how a company creates or builds a product. That is a complex activity that includes a wide range of machinery, tools and equipment with various levels of automation using computers, robots and high-end technology.

We are always evaluating every aspect of our production line and thus striving to improve our production processes.

The latest addition to our production equipment is the e-camguard system package from Plassteze. E-camguard is a complete system that helps transform the plastic injection machine into an intelligent one. It consists of camera, near IR lights, computer with smart software, IO Box, all connecting cables and mounting magnets.

If any malfunction is detected during the injection process, the system which is interlocked with the machine, immediately stops the ejection or mould closure.

With it’s sharp like-an eagle- vision, controlled by the smart software it detects:

- if any part is missing

- if the parts are not fully ejected

- if there is improper movement

- if there is improper retraction of ejectors

- it the inserts are placed correctly before injection

- if there are abnormal flashes occurring

- if there is shortage in the filling of the parts

The e-camguard system helps the machine avoid accidental damages and therefore improve operating efficiency.

We continue to assess the current processes, products and services to ensure that the output is maximized and damages are minimized.